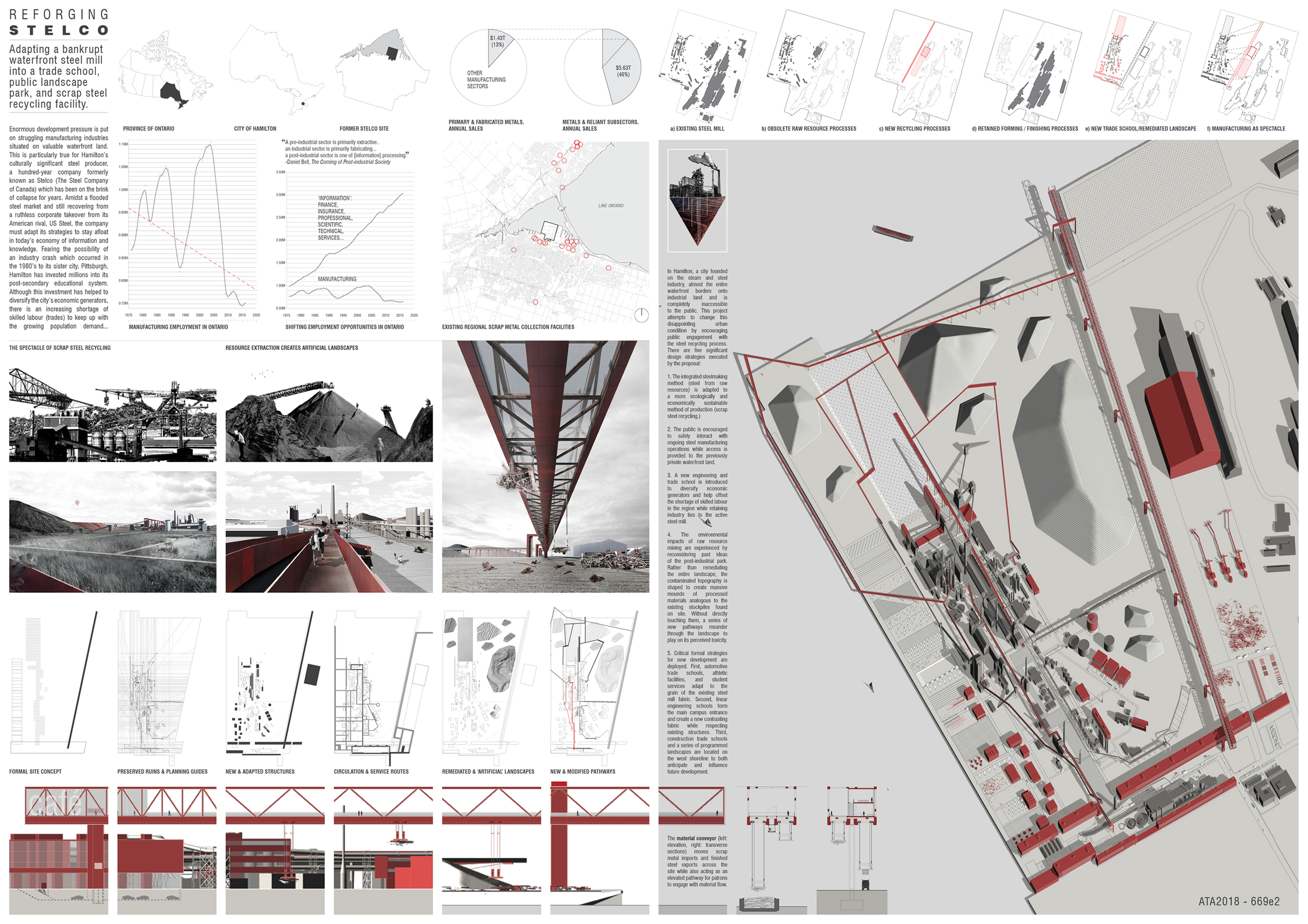

Enormous development pressure is put on struggling manufacturing industries situated on valuable waterfront land. This is particularly true for Hamilton’s culturally significant steel producer, a hundred-year company formerly known as Stelco (The Steel Company of Canada) which has been on the brink of collapse for years. Amidst a flooded steel market and still recovering from a ruthless corporate takeover from its American rival, US Steel, the company must adapt its strategies to stay afloat in today’s economy of information and knowledge.

Fearing the possibility of an industry crash which occurred in the 1980's to its sister city, Pittsburgh, Hamilton has invested millions into its post-secondary educational system. Although the investment has helped to diversify the city’s economic generators, there is an increasing shortage of skilled labour (trades) to keep up with the growing population demand in the region. In Hamilton, a city founded on the steam and steel industry, almost the entire waterfront borders onto industrial land and is completely inaccessible to the public. This project attempts to change this disappointing urban condition by encouraging public engagement with the steel recycling process. There are five significant design strategies executed by the proposal: 1. The integrated steelmaking method (steel from raw resources) is adapted to a more ecologically and economically sustainable method of production (scrap steel recycling.) 2. The public is encouraged to safely interact with ongoing steel manufacturing operations while access is provided to the previously private waterfront land. 3. A new engineering and trade school is introduced to diversify economic generators and help offset the shortage of skilled labour in the region while retaining industry ties to the active steel mill.

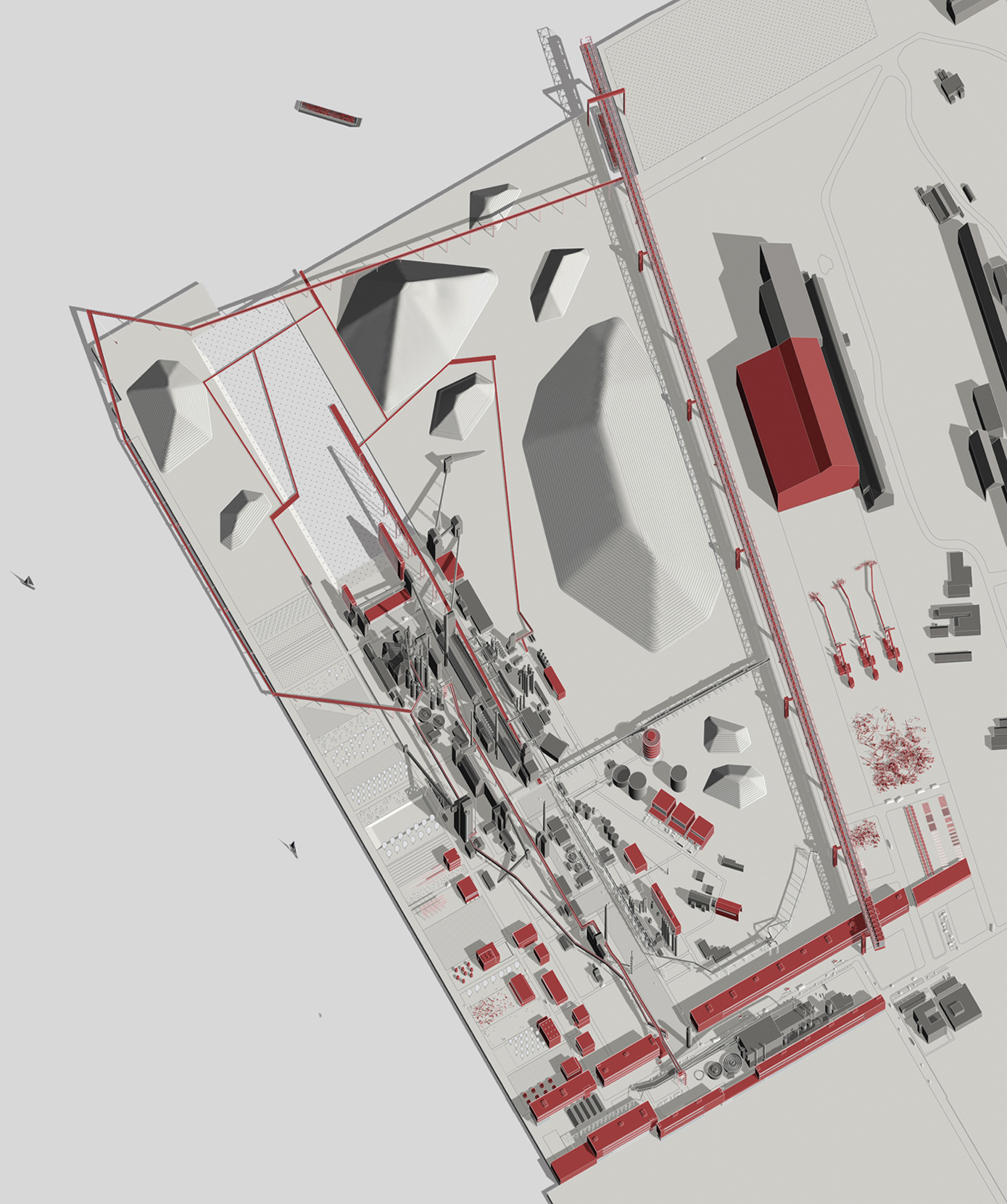

4. The environmental impacts of raw resource mining are experienced by reconsidering past ideas of the post-industrial park. Rather than remediating the entire landscape, the contaminated topography is shaped to create massive mounds of processed materials analogous to the existing stockpiles found on site. Without directly touching them, a series of new pathways meander through the landscape to play on its perceived toxicity. 5. Formal strategies for new development are deployed: automotive trade schools, athletic facilities, and student services adapt to the grain of the existing steel mill fabric; linear engineering schools form the main campus entrance and create a contrasting fabric while respecting existing structures; and construction trade schools and a series of programmed landscapes are located on the west shoreline to both anticipate and influence future development. One of the most exciting aspects of this proposal is the material conveyor which visually and conceptually splits active steelmaking operations from the public school and landscape park. The conveyor moves scrap metal imports and finished steel exports across the site while also acting as an elevated pathway for patrons to engage with material flow. To bring people up to the linear platform a café is placed inside the truss structure overlooking the south entrance to give people a privileged view of the kinetic recycling spectacle.

The Board: